INJECTION DISPENSER

Development of a medical syringe dispenser by the GEC team using electronics, 3D printing, and engineering.

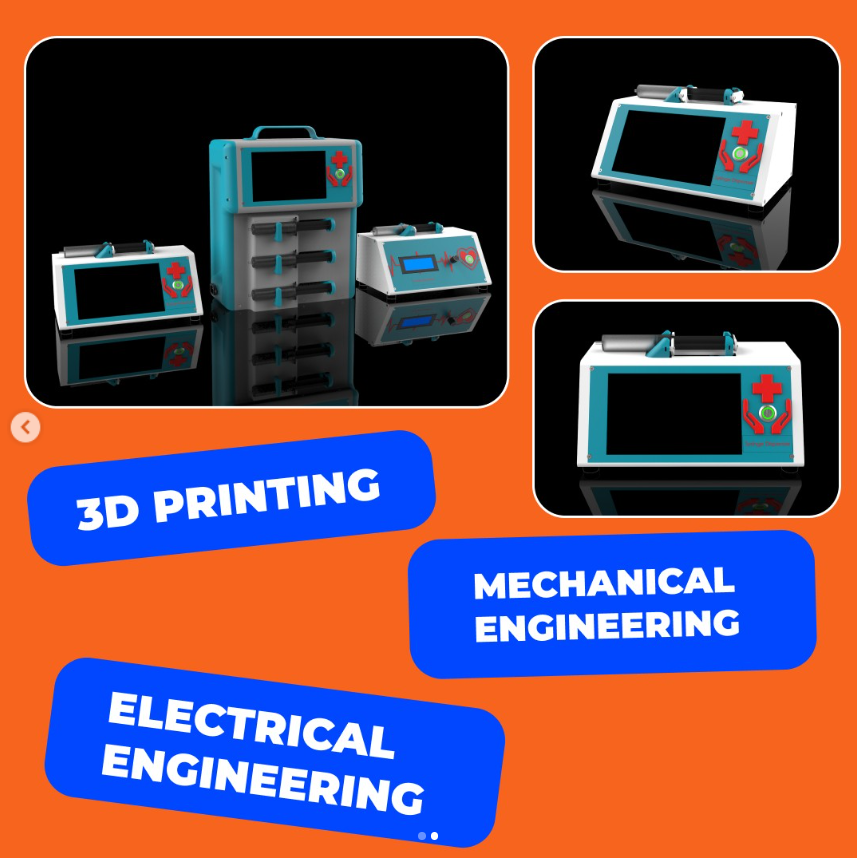

An essential part of the syringe dispenser’s development was the use of modern 3D printing technology. The team’s mechanical engineer created a detailed device model using SolidWorks, considering all necessary aspects and requirements. Subsequently, the model was 3D-printed using durable ABS plastic. The advantage of 3D printing lies in its ability to rapidly prototype and create complex shapes, optimizing the dispenser’s design and reducing production costs.

Another key component of the dispenser was the electronics. It is based on the Nemo 17 motor and Arduino Mega board, providing control and operation management. A 12V 6A power supply system ensures stable electrical power for the device. For user convenience, a 7-inch touchscreen display was installed, allowing intuitive interaction with the dispenser, along with a sturdy backlit button with a lock. The electronics were implemented using the C++ programming language in the Visual Studio environment.

The GEC engineering team paid special attention to the engineering aspect. All fasteners, such as the dispenser fasteners, motor fasteners, and front panel, were made from high-quality materials, ensuring reliable and durable dispenser operation. The use of single-row, dual 8mm diameter sliding bearings, 8mm shafts, and compensating couplings guarantees smooth and precise device functioning.

The use of the Arduino Mega platform and the C++ programming language has provided a reliable and flexible control system, allowing precise management of medication administration and customization of the syringe dispenser to meet specific patient needs. The touchscreen display and sturdy backlit button ensure user-friendliness, making the syringe dispenser accessible to both medical staff and patients.

An important aspect of the development was the integration of 3D printing technology. Our experts actively implemented this method to make the syringe dispenser more affordable and cost-effective. 3D printing allowed us to create an optimized and robust device design, streamlining the manufacturing processes. As a result, syringe dispensers can be available to a wide range of medical facilities, including regions with limited resources.

Furthermore, the role of engineering in the dispenser’s development is worth mentioning. Careful selection of high-quality materials and proper engineering decisions in component choices ensured the device’s reliability and durability. Its compact size and user-friendliness make the syringe dispenser convenient for medical personnel and enable patients to use it independently when needed.

Medical development by the GEC ENGINEERING team

The GEC Engineering team always strives to apply cutting-edge technologies in various fields, and medicine is no exception. The development of a medical syringe dispenser has become one of our team’s major contributions to the medical field. This device, created using advanced methods of electronics, 3D printing, and engineering, represents a significant achievement that will bring substantial benefits to the medical community and patients.

The application of the syringe dispenser in medicine is crucial for precise and safe medication delivery. This device ensures patients receive the necessary dosage of medication over an extended period, which is particularly important for treating chronic conditions. By providing accurate control over medication administration, syringe dispensers minimize the risk of overdose and ensure optimal treatment.

This development represents an innovative solution that enhances the quality of treatment and ensures precision in medication delivery. It will find applications in various medical areas, including oncology, neurology, gastroenterology, and other medical practices.